Metal building purlins are strong, horizontal supports for metal roofs. You need them to keep your building safe and steady. If you use purlins made with modern standards and take care of them, your building will last longer. Look at the table below to see how purlins help buildings last:

Description | Impact on Longevity |

Modern designs and materials make purlins work better. | Makes buildings stronger and steadier. |

Good design and care stop problems from happening. | Helps buildings last longer. |

Adding purlins when updating meets new rules. | Makes buildings tougher overall. |

Key Takeaways

Metal building purlins help hold up roofs and walls. They keep buildings safe and steady in all kinds of weather.

You need to pick the right purlin type, like C or Z. This choice depends on how heavy and wide your building is.

Checking and taking care of purlins often stops them from sagging. It also helps stop other building problems and makes your building last longer.

Steel purlins are better than wood ones in some ways. They do not rot or get eaten by termites, so you spend less on repairs.

Purlins must be put in the right way and spaced out well. This spreads out the weight and keeps the roof from getting weak or falling down.

Metal Building Purlins

What Is a Purlin?

Purlins are found in almost every metal roof. A purlin is a horizontal piece that holds up the roof. It helps carry the weight from the roof sheets. Purlins run across the roof and connect to the main frames or walls. They help keep the roof steady and strong.

In metal buildings, metal purlins hold up the roof panels. They move the weight to the main steel frames. Purlins handle two main types of loads:

Dead loads: These are things like roof panels and insulation.

Live loads: These are things like snow, rain, and workers.

Steel purlins are chosen because they do not rot or get eaten by termites. They do not bend easily and stay strong in many climates. Aluminum purlins are lighter and do not rust, but steel purlins can hold more weight. Steel is more reliable for most metal building purlins.

Tip: You can ask your supplier for special sizes and lengths for your project.

Here is a table that shows common materials and their strengths:

Material | Strengths |

Steel | Holds a lot of weight, does not rust, lasts long |

Aluminum | Light, does not rust, works in many places |

Metal purlins come in many shapes and sizes. Most commercial buildings use purlins that are 4 to 12 inches wide. Flange widths are usually between 1-½ and 4 inches. Here are some common sizes:

Dimension A | Dimension B | Dimension C | Available Gauges | Finish | Weight per LF |

4" | 2-1/2" | 2-1/2" | 16G & 14G | GALVANIZED | 2.04 LBS |

6" | 2-1/2" | 2-1/2" | 16G, 14G & 12G | GALVANIZED | 2.45 LBS |

8" | 2-1/2" | 2-1/2" | 16G, 14G & 12G | GALVANIZED | 2.45 LBS |

10" | 3" | 3" | 16G, 14G & 12G | GALVANIZED | 2.45 LBS |

12" | 3" | 3" | 14G & 12G | GALVANIZED | 4.88 LBS |

14" | 3" | 3" | 14G & 12G | GALVANIZED | 5.39 LBS |

Role in Metal Buildings

Metal purlins help keep buildings safe and steady. They support the roof and walls, even in storms or strong winds. Purlins spread out the weight so the building can hold more.

Metal building purlins give important support to roofs and walls.

They spread out weight, which keeps the building strong.

Steel purlins help buildings stand up to strong winds and bad weather.

Steel purlins are better than wood. They do not rot or get termites. They are stronger for their weight, so buildings can hold more. You also save money on repairs over time.

C purlins are used for small and medium projects. They spread out weight and last a long time. Z purlins are best for big projects that need strong support. C purlins are often made from galvanized steel to stop rust.

Here is a quick list of what metal purlins do for your building:

Hold up roof panels and move weight to main frames.

Handle dead and live loads.

Make buildings steadier in bad weather.

Lower repair costs by stopping damage.

Metal building purlins are the backbone of the roof system. They keep everything in place and help your building last longer.

Why Purlins Matter

Structural Support

You need strong support for any metal building roof system. Metal purlins act as the backbone for your roof. They hold up the weight of roof panels, insulation, and anything else placed on top. When you use steel purlins, you get extra strength and durability. These purlins connect to the main frames and help your building stand up to wind, rain, and snow.

Note: Metal purlins for roofing do not rot or warp like wood. You get a longer-lasting structure.

Purlins work together with beams and columns. They spread the weight across the whole building. This teamwork keeps your roof steady and safe. If you use the right size and spacing, you avoid weak spots and make your building last longer.

Load Distribution

The purpose of purlins is to move weight from the roof to the main structure. You want your roof to handle heavy loads, like snow or equipment. Metal purlins help by spreading this weight out. If you use the wrong type or spacing, you risk overstressing your roof.

The typical allowable pressure for a 6-span purlin line is 19.6 psf.

Some roofs need to handle up to 30.0 psf.

If your purlins are overstressed, you can add more lines or reinforce them.

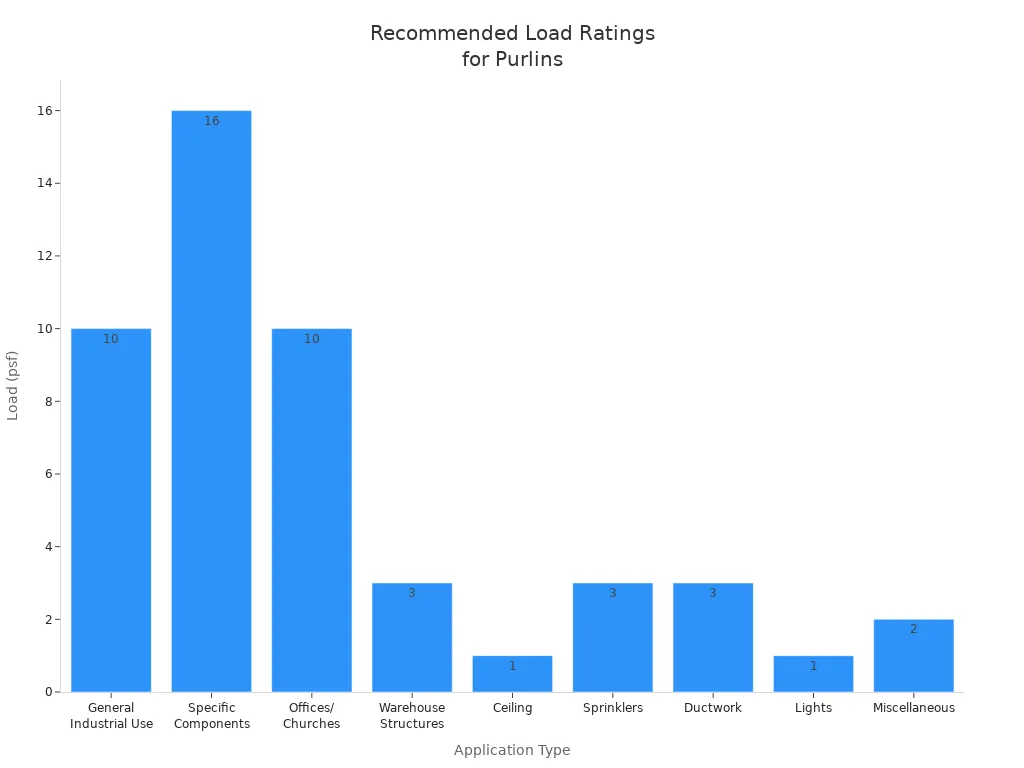

Here is a table showing recommended load ratings for different uses:

Application Type | Recommended Load (psf) |

General Industrial Use | 5 to 10 |

Specific Components | Up to 16 |

Offices/Churches | 5 to 10 |

Warehouse Structures | 3 |

Ceiling | 1 |

Sprinklers | 3 |

Ductwork | 3 |

Lights | 1 |

Miscellaneous | 2 |

Purlins act as horizontal beams. They take the weight from the roof and move it to the main frames. This even spread of weight keeps your building stable. You can use tools like the SkyCiv Purlin Load Capacity Calculator to check if your metal purlins can handle the load. These tools use simple formulas based on roof thickness, purlin spacing, and material strength.

The calculator supports both C and Z purlin sections.

It uses rules from AISI, ASCE, and AISC.

You can avoid complex math and still get safe results.

If you use hat purlins for heavy loads, you risk sagging or warping. Always match the purlin type to your building's needs.

Preventing Roof Sagging

Roof sagging is a big problem in metal buildings. If your purlins cannot hold the weight, the roof may bend or even collapse. You can stop this by using the right support and bracing.

Add extra lines of purlin braces for long spans.

Install more rows of bracing in each bay.

Use pre-punched holes in purlins for easy brace installation.

Here is a table of strategies to prevent roof sagging:

Strategy | Description |

Identifying weak areas | Check for damage or weak spots in your roof. |

Applying additional supports | Add more purlins or braces to spread out the weight. |

Upgrading materials | Replace damaged purlins with stronger steel purlins. |

Implementing proper bracing | Use bracing to keep purlins from moving too much. |

If you ignore sagging, you risk serious problems:

Consequence | Description |

Roof Collapse | The roof can fall in if it does not have enough support. |

Water Damage | Gaps from sagging let water in, damaging walls and ceilings. |

Mold Growth | Water leaks can cause mold, which is bad for health. |

Sagging can stretch seams and cause leaks.

Bowed wall panels may misalign and stress fasteners.

Crushed insulation can break vapor barriers and lower energy efficiency.

A sagging roof is dangerous. It can collapse and hurt people or damage property. You protect your building by choosing the right metal purlins and checking them often.

Types of Metal Purlins

There are two main types of metal purlins. Each type has its own shape and job. You pick the right one based on your project and how much weight it needs to hold.

C-Shaped Metal Purlins

C purlins look like the letter "C." You find them in small sheds and farm buildings. They work best for short spaces and steady loads. Their shape makes them easy to put in place. C purlins give strong support for flat uses. They help keep roofs safe and steady.

Here is a table that compares c purlins and z purlins:

Cross-Sectional Shape | C Purlins | Z Purlins |

Shape | Looks like 'C', same on both sides | Looks like 'Z', has joined grooves |

Load-Bearing Capacity | Good for short spaces | Good for bigger loads |

C purlins come in many sizes. Some common sizes are 4-inch by 2-1/2-inch and 6-inch by 2-1/2-inch. Steel purlins in these sizes hold up metal roofs well.

Z-Shaped Metal Purlins

Z purlins look like the letter "Z." You see them in big roofs and walls. Z purlins work well for long spaces and heavy loads. They overlap at the joints to make them stronger. This makes z purlins great for large roofs and farm buildings.

You can use z purlins for roof frames, wall support, and other building parts. Z purlins stand up to strong winds and heavy snow. They fit tightly on rafters and make buildings steadier. You can pick sizes like 8-inch by 2-1/2-inch or 10-inch by 3-inch for more strength.

Here are some ways people use z purlins:

Roofs in warehouses and factories

Wall panels outside buildings

Floors above ground and canopies

Barns and animal shelters

Choosing the Right Type

You need to think about a few things when picking c purlins or z purlins. The weight your building needs to hold is most important. Z purlins hold more weight and cover longer spaces. C purlins work for short spaces and are quick to install. You should check the size and longest space each type can cover.

Purlin Size | Maximum Span |

2-inch by 4-inch | 4 feet |

2-inch by 6-inch | 6 feet |

You should also think about the weather. Steel purlins with special coatings last longer in wet or salty places. The maker's skill matters too. You want strong metal purlins for safety and long life.

Tip: Pick metal purlins that fit your building's size and weight needs. Overlapping z purlins makes big roofs stronger.

The type, size, and use of metal purlins are very important in building design. Picking the right one helps your metal purlins hold up the roof and walls for a long time.

Purlin Installation & Care

Installation Basics

You want metal purlins to last a long time. First, check the design with an engineer. Always follow the maker's rules for spacing and alignment. Use bolts or screws to attach purlins. Make sure insulation does not move purlins. Fasten all parts tightly. Strong bolts help hold more weight. Add diagonal bracing for extra strength. Check your work to catch mistakes early.

Here is a table that shows common mistakes and ways to avoid them:

Mistake Type | How to Avoid |

Incorrect Purlin Spacing | Measure and follow spacing guidelines |

Poor Fastening | Use proper bolts and screws |

Ignoring Load-Bearing Capacity | Check load ratings before installation |

Misalignment | Level and align each purlin |

Lack of Corrosion Protection | Apply coatings like galvanization |

Overlooking Expansion/Contraction | Allow for temperature changes in design |

Tip: Hongfa Steel makes steel buildings. You can trust their products for easy installation and care.

Spacing and Sizing

Spacing depends on roof load and how far it spans. You need to figure out the loads before you set purlins. Wider roofs need purlins closer together. Roof panel thickness, roof angle, and local rules change spacing. Homes use 24 to 30 inch spacing. Big roofs may use up to 5 feet if reinforced. Snow and wind mean you need tighter spacing and more bracing.

If you live where winds are strong, use closer frame spacing. Pick thicker steel purlins for more strength. Hat-channel purlins make roofs stronger. Concrete anchors keep everything in place. Vertical roof panels and more screws help fight wind.

Note: You can check the Load Requirements page for your address. This gives you the right details for your building.

Material and Coating

Steel purlins last longer than wood ones. They do not bend or twist. Special coatings like hot-dip galvanization stop rust. Powder coating makes a hard finish. Galvanization uses zinc to protect steel. Powder coating works better than paint to stop rust.

Coating Type | Protection Level | Maintenance Needs |

Hot-Dip Galvanize | High | Low |

Powder Coating | High | Low |

Paint | Medium | Medium |

Tip: Rhino metal building purlins use strong coatings. This helps rhino purlins last longer and stay tough.

Maintenance Tips

You keep purlins strong by checking them twice a year. Look for rust, leaks, or broken parts. Clear leaves and dirt from the roof and gutters. Check seams, screws, and roof panels. Tighten bolts and screws often. Put on rust-proof coatings when needed. Change damaged insulation. Oil moving parts. Seal gaps to keep bugs out. Make sure water drains well. Remove snow and ice fast. Clean and paint rusty spots. Get a pro to inspect every year.

Reminder: Purlins are horizontal steel pieces in a building. Regular care helps your building system last many years.

Conclusion

Metal building purlins help your building stay strong. You need to pick the right type for your project. Install purlins with care and check them often. This helps your building last a long time.

Choose strong purlins to keep your building safe.

Put each purlin in place by following expert tips.

Look at your purlins every year and fix any problems.

You can look at Hongfa Steel for good metal building purlins. It gives you more info and help for your project.

FAQ

What do metal building purlins do?

Metal building purlins support your roof panels. They move weight to the main frame. You get a stronger, safer building. Purlins help your roof last longer.

How do you choose between C and Z purlins?

You pick C purlins for short spans and simple jobs. Z purlins work best for long spans and heavy loads. Use this table for a quick guide:

Purlin Type | Best Use |

C | Small buildings |

Z | Large buildings |

How often should you inspect metal purlins?

You check metal purlins twice each year. Look for rust, loose bolts, or damage. Fix problems fast. Regular checks keep your building safe.

Can you paint metal purlins?

Yes, you can paint metal purlins. Use rust-proof paint or powder coating. It protects steel from moisture. You get longer life and better looks.

What happens if purlins sag?

Sagging purlins cause roof leaks and damage. You risk collapse. You must add bracing or replace weak purlins. Quick action keeps your building safe.